The Future in a Construction. WorldWide.

Skytel 41A, Remarkable Height and Reach

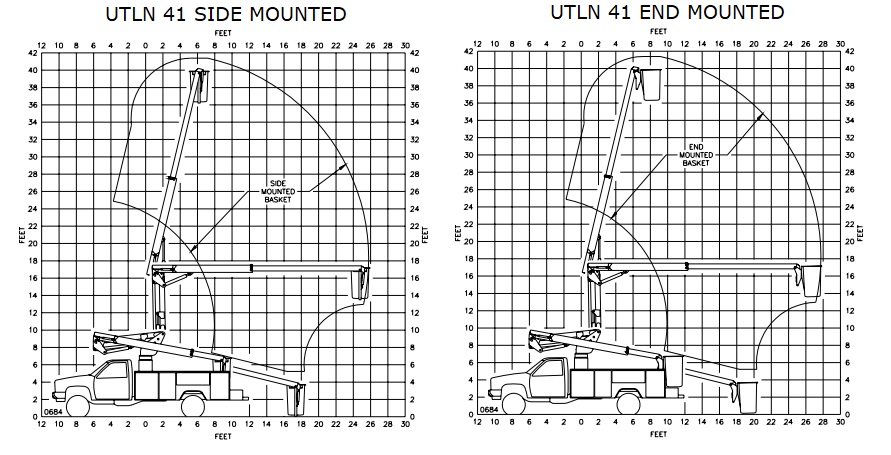

Introducing the SkyTel 41A, an aerial lift designed to elevate your work to new heights equiped with a telescopic upper boom. With an impressive working height of 41 feet 9 inches (12.72 meters), it enables you to tackle elevated tasks effortlessly, including maintenance, repairs, and inspections.

What sets the SkyTel 41 apart is its remarkable side reach capability, extending up to 25 feet 9 inches (7.86 meters), providing safe and efficient access to challenging and distant work areas.

Side Mounted Basket Specifications

Models

Basket Bottom Height1

Working Height1

Standard Basket Capacity

Maximum Basket Capacity

Maximum Horizontal Reach

Lower Boom Articulation

Upper Boom Articulation

Upper Boom Extension

Insulation Gap Fully Retracted

Insulation Gap Extended

Stowed Travel Height1

Electrical System Voltage

Rotation

Hydraulic System Operating Pressure

Unit Weight

UTLN41 (Non-Insulated)

36 ft. 9 in. (11.19m)

41 ft. 9 in. (12.72m)

300 lbs. (136kg)

350 lbs. (159kg)

28 ft.2 in.(8.58m)

-60 to 900 (Lower Boom Articulation)

-140 to 780 (Upper Boom Articulation)

108 in. (2.74m) (Upper Boom Extension)

n/a

n/a

10 ft. 2 in. (3.10m) (Stowed Travel Height)

12VDC (Electrical System Voltage)

5400 (Rotation, Non-Continuous)

2200PSI (155kg/cm2)

2324 lbs.(1054.1kg)

UTLI41A (Insulated)

36 ft. 9 in. (11.19m)

41 ft. 9 in. (12.72m)

300 lbs. (136kg)

400 lbs. (181kg)

27 ft.9 in.(8.46m)

-60 to 900 (Lower Boom Articulation)

-140 to 780 (Upper Boom Articulation)

108 in. (2.74m) (Upper Boom Extension)

30 in. (0.76m) (Insulation Gap Fully Retracted)

42 in. (1.07m) (Insulation Gap Extended)

10 ft. 2 in. (3.10m) (Stowed Travel Height)

12VDC (Electrical System Voltage)

5400 (Rotation, Non-Continuous)

2500 PSI (176kg/cm2)

2339 lbs.(1015.2kg)

1. Based on 36 in (0.91m) chassis frame height.

Chassis Requirements:

Requirement

GVWR2,3

Front GAWR2,4

Rear GAWR2,4

Cab to Rear Axle

Frame Section Modulus

RBM of Frame

Minimum

15,000 lbs. (6804kg)

5,000 lbs. (2268kg)

11,000 lbs. (4990kg)

60 inches

8.0 cubic inches

280,000 in.-lbs.

Recommended

15,000 lbs. (6804kg)

6,000 lbs. (2722kg)

11,000 lbs. (4990kg)

84 in. (2.13m)

8.0 in.3 (131cm3)

280,000 in.-lbs. (31640N-m)

1. Based on 25.5 in.(0.65m) chassis frame height.

2. Actual curb weight for stability and the required GVWR and GAWR can vary significantly with vehicle stiffness, suspension stiffness, vehicle wheelbase, aerial lift mounting location, body, accessories, ballast (if required), platform capacity and desired payload. Actual weight for stability must be determined by testing in accordance with the ANSI A92.2 standard.

3. GVWR means gross vehicle weight rating.

4. GAWR means gross axle weight rating.

Fille Sources

R:\Manuals\Current Production Manuals\700616 UTLN41&UTLN46 Operator's Manual Nov02.pdf

R:\Manuals\Current Production Manuals\701082 UTLI41A&UTLI46A Operator's Manual Sep17.pdf

End Mounted Basket Specifications

Model

Basket Bottom Height1

Working Height1

Standard Basket Capacity

Maximum Basket Capacity

Maximum Horizontal Reach

Lower Boom Articulation

Upper Boom Articulation

Upper Boom Extension

Insulation Gap Fully Retracted

Insulation Gap Extended

Stowed Travel Height1

Electrical System Voltage

Rotation

Hydraulic System Operating Pressure

Unit Weight

UTLN41 (Non-Insulated)

36 ft. 9 in. (11.19m)

41 ft. 9 in. (12.72m)

300 lbs. (136kg)

350 lbs. (159kg)

28 ft. 2 in. (8.58m)

-60 to 900 (Lower Boom Articulation)

-140 to 780 (Upper Boom Articulation)

108 in. (2.74m) (Upper Boom Extension)

n/a

n/a

10 ft. 2 in. (3.10m) (Stowed Travel Height)

12VDC (Electrical System Voltage)

5400 (Rotation, Non-Continuous)

2200PSI (155kg/cm2)

2374 lbs. (1076.1kg)

UTLNI41A (Insulated)

36 ft. 9 in. (11.19m)

41 ft. 9 in. (12.72m)

300 lbs. (136kg)

400 lbs. (181kg)

27 ft. 9 in. (8.46m)

-60 to 900 (Lower Boom Articulation)

-140 to 780 (Upper Boom Articulation)

108 in. (2.74m) (Upper Boom Extension)

30 in. (0.76m) (Insulation Gap Fully Retracted)

42 in. (1.07m) (Insulation Gap Extended)

10 ft. 2 in. (3.10m) (Stowed Travel Height)

12VDC (Electrical System Voltage)

5400 (Rotation, Non-Continuous)

2500 PSI (176kg/cm2)

2333 lbs. (1058.2kg)

1. Based on 36 in (0.91m) chassis frame height.

Fille Sources

R:\Manuals\Current Production Manuals\700616 UTLN41&UTLN46 Operator's Manual Nov02.pdf

R:\Manuals\Current Production Manuals\701082 UTLI41A&UTLI46A Operator's Manual Sep17.pdf

End Mounted Basket with Manual Rotator

Model

Basket Bottom Height1

Working Height1

Standard Basket Capacity

Maximum Basket Capacity

Maximum Horizontal Reach

Lower Boom Articulation

Upper Boom Articulation

Upper Boom Extension

Insulation Gap Fully Retracted

Insulation Gap Extended

Stowed Travel Height1

Electrical System Voltage

Rotation

Hydraulic System Operating Pressure

Unit Weight

UTLN41 (Non-Insulated)

36 ft. 9 in. (11.19m)

41 ft. 9 in. (12.72m)

300 lbs. (136kg)

350 lbs. (159kg)

28 ft. 2 in. (8.58m)

-60 to 900 (Lower Boom Articulation)

-140 to 780 (Upper Boom Articulation)

108 in. (2.74m) (Upper Boom Extension)

n/a

n/a

10 ft. 2 in. (3.10m) (Stowed Travel Height)

12VDC (Electrical System Voltage)

5400 (Rotation, Non-Continuous)

2200PSI (155kg/cm2)

2412 lbs. (1094.1kg)

UTLNI41A (Insulated)

36 ft. 9 in. (11.19m)

41 ft. 9 in. (12.72m)

300 lbs. (136kg)

350 lbs. (159kg)

28 ft. 5 in. (8.65m)

-60 to 900 (Lower Boom Articulation)

-140 to 780 (Upper Boom Articulation)

108 in. (2.74m) (Upper Boom Extension)

30 in. (0.76m) (Insulation Gap Fully Retracted)

42 in. (1.07m) (Insulation Gap Extended)

10 ft. 2 in. (3.10m) (Stowed Travel Height)

12VDC (Electrical System Voltage)

5400 (Rotation, Non-Continuous)

2500 PSI (176kg/cm2)

2371 lbs. (1075.2kg)

1. Based on 36 in (0.91m) chassis frame height.

Fille Sources

R:\Manuals\Current Production Manuals\700616 UTLN41&UTLN46 Operator's Manual Nov02.pdf

R:\Manuals\Current Production Manuals\701082 UTLI41A&UTLI46A Operator's Manual Sep17.pdf

End Mounted Basket with Hydraulic Rotator

Model

Basket Bottom Height1

Working Height1

Standard Basket Capacity

Maximum Basket Capacity

Maximum Horizontal Reach

Lower Boom Articulation

Upper Boom Articulation

Upper Boom Extension

Insulation Gap Fully Retracted

Insulation Gap Extended

Stowed Travel Height1

Electrical System Voltage

Rotation

Hydraulic System Operating Pressure

Unit Weight

UTLN41 (Non-Insulated)

36 ft. 9 in. (11.19m)

41 ft. 9 in. (12.72m)

300 lbs. (136kg)

350 lbs. (159kg)

28 ft. 2 in. (8.58m)

-60 to 900 (Lower Boom Articulation)

-140 to 780 (Upper Boom Articulation)

108 in. (2.74m) (Upper Boom Extension)

n/a

n/a

10 ft. 2 in. (3.10m) (Stowed Travel Height)

12VDC (Electrical System Voltage)

5400 (Rotation, Non-Continuous)

2200 PSI (155kg/cm2)

2421 lbs. (1098.1kg)

UTLNI41A (Insulated)

36 ft. 9 in. (11.19m)

41 ft. 9 in. (12.72m)

300 lbs. (136kg)

350 lbs. (159kg)

28 ft. 5 in. (8.65m)

-60 to 900 (Lower Boom Articulation)

-140 to 780 (Upper Boom Articulation)

108 in. (2.74m) (Upper Boom Extension)

30 in. (0.76m) (Insulation Gap Fully Retracted)

42 in. (1.07m) (Insulation Gap Extended)

10 ft. 2 in. (3.10m) (Stowed Travel Height)

12VDC (Electrical System Voltage)

5400 (Rotation, Non-Continuous)

2500 PSI (176kg/cm2)

2380 lbs. (1079.5kg)

1. Based on 36 in (0.91m) chassis frame height.

Fille Sources

R:\Manuals\Current Production Manuals\700616 UTLN41&UTLN46 Operator's Manual Nov02.pdf

R:\Manuals\Current Production Manuals\701082 UTLI41A&UTLI46A Operator's Manual Sep17.pdf

UTEM UTLN41 and UTLN46 SkyTel Features and Benefits

A non-insulated articulating/telescoping boom unit designed to mount on a chassis over 15,000 lb. GVWR providing excellent maneuverability.

Feature: Strong in Structure, Light in Weight

Benefit: Capable of mounting on a 15,000 lb. GVWR chassis providing working heights from 41 feet 9 inches to 45 feet 9 inches and horizontal reach from 25 feet 9 inches to 28 feet 5 inches on a very maneuverable vehicle, increasing productivity.

Feature: Articulating/Telescoping Boom Assembly

Benefit: Up and over capability permits safe access across obstacles such as parked cars, sidewalks, landscaping, etc. Articulating lower boom provides additional horizontal reach. Telescoping upper boom allows easy ground access to the basket.

Feature: Pedestal Houses Hydraulic Oil Reservoir with Sight Gauge, Oil Filter and Electrical Components

Benefit: Protected from damage yet easy to access for maintenance and service reducing the end user cost.

Feature: Joystick Boom Control with Enable Control

Benefit: One hand control of all boom movements even with the enable control.

Feature: Upper Controls Mounted Beside the Platform not on the Boom

Benefit: Controls are stationary relative to the operator as opposed to being located on the boom where the position of the controls changes with boom elevation.

Feature: 10 Micron Return Filter and 100 Mesh Suction Line Screen

Benefit: Constant cleaning and filtering of hydraulic oil protects hydraulic components.

Feature: Integral Holding Valves on Extension and Boom Cylinders

Benefit: Lock cylinders in position in the unlikely event of a hose or fitting failure. Integral holding valves eliminate manifold leakage and are less susceptible to damage.

Feature: Unloader Valve

Benefit: Integral to the main control valve, the unloader valve diverts hydraulic oil away from boom control solenoid valves preventing uncontrolled movement in the event a control

valve fails to return to the neutral position.

Feature: Gravity Leveled Basket with Dampener

Benefit: Self-leveling of the basket with dampened motion while the boom is being positioned, affording safety and comfort for the operator.

Feature: Basket Caliper Brake System

Benefit: Operator can easily lock or release the basket brake under load to allow the basket to level unlike locking pin assemblies, which can be difficult to release.

Feature: Zinc Plated Pivot Pins

Benefit: Prevents corrosion, reduces maintenance and costly downtime.

Feature: Non-Lube Bearings Used at all Pivot Points

Benefit: Reduced downtime for maintenance.

Feature: Infinitely Adjustable Outer Boom Wear Pads

Benefit: Easily adjusted or replaced without dismantling boom. No shims are required for adjustment.

Feature: Dual Holding Valves on Extension Cylinder

Benefit: Prevents the inner boom from drifting in or out from the stowed position.

Feature: 540* Non-Continuous Rotation with Mechanical Stop

Benefit: Provides a work envelope all the way around the unit with no annoying "dead spots". It is much less complicated and requires less maintenance than continuous rotation or other non-continuous rotation systems with electrical limit switches or solenoid valves.

Feature: Shear-Ball Rotation Bearings

Benefit: Smoother rotation and long life resulting in lower maintenance and operating costs.

Feature: Hour-Glass Shaped Worm Engages Rotation Bearing

Benefit: Prevents free wheeling in the event of hydraulic failure. Distributes load over multiple teeth plus fewer moving parts providing long life and requiring less maintenance.

Feature: Exposed End of Worm Shaft is Hexagonal

Benefit: Allows for manual rotation in an emergency or for maintenance.

Feature: Control Cables and Hoses Routed Through Hose Carrier Inside Boom

Benefit: Eliminates damage to hoses and cables from contact with foreign obstacles causing expensive repairs and downtime.

Feature: Smooth Operation, Low Friction Components

Benefit: Reduces amp-hour requirements of batteries allowing up to fifty cycles even with the vehicle engine off with fully charged batteries.

Feature: Serviceable and Reliable Electrical Components

Benefit: Sealed electrical connectors and switches, plug-in relays and user-friendly controls provide for safe operation, less maintenance, and more trouble-free operation.

Feature: Numerous Options are Available

Benefit: Permits customization of an aerial lift to fit each specific customer’s needs. The most popular options are listed below:

- HE Hydraulics—Provides for a PTO or engine accessory belt-driven hydraulic pump for the most demanding requirements. Can even be used to operate hydraulic tools.

- EH Hydraulics—Provides a 12VDC motor/pump to operate the aerial lift. This configuration conserves fuel, reduces engine wear, reduces pollution and allows operation inside buildings. The batteries are charged by the vehicle electrical system.

- DP Hydraulics—Provides for either a PTO or engine accessory belt-driven hydraulic pump if the vehicle engine is running or a 12VDC motor/pump if the vehicle engine is not running to operate the aerial lift. This configuration provides the versatility and features of both HE and EH Hydraulics.

- Hydraulic Leveling—Provides for automatic leveling of the platform and a means to tilt the platform for clean out or rescue with upper and lower controls.

- Proportional Upper Controls—Provides exceptional “feathering” of the boom controls.

- 12VDC Powered Emergency Lowering

- Hydraulic Tool Circuit (HE and DP Units Only)

- Outer Boom Lift Eye—Provides for limited material lifting.

- Electric Tool Circuit

- Nitrogen/Air Line to Platform

- End Mounted Basket

- Manual Basket Rotator

- Hydraulic Basket Rotator

- Splicing Basket

- Round Rotating Splicing Basket

- Two-Speed Engine Throttle Control

- Basket Covers

- Adjustable Basket Seat

- Basket Heater

- Tool Tray

- Outriggers

- Torsion Bars

- Special Paint

T:\1 UTEM\UTEM Sales Manual\2008 UTEM Sales Manual\Sec5--SkyTel\Skytel Specs (Word) UTLN41 and UTLN46 SkyTel Features and Benefits.doc 26Mar04