The Future in a Construction. WorldWide.

Elevating Your Reach, Lighting Your Way!

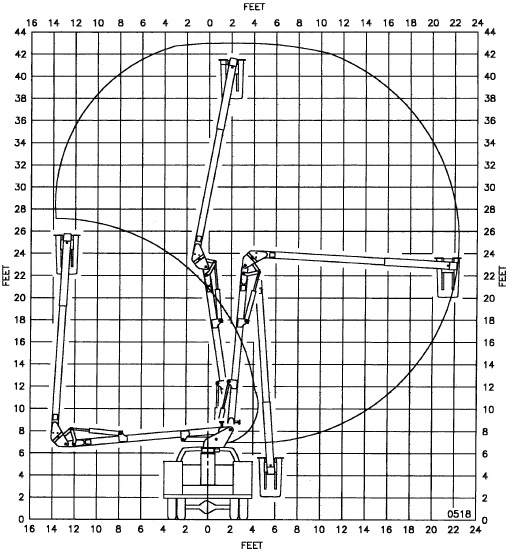

The UTEM SkyJacker is a series of articulated/non-overcenter aerial devices tailored for tasks such as power lines, lighting and signage maintenance, particularly suited for use by municipalities, school districts, universities, and sign contractors.

The SkyJacker comes in four models, ranging from 30 to 43 feet in working height and 14 to 21 feet in side reach. These models are adaptable for a wide range of applications, making them versatile solutions for different industries and organizations. We offer isulated and non- isulated versions.

Dimensional Specifications:

-

Basket to bottom Height (1)

Working Height (1)

Horizontal Side Reach

Unit Weight (4)

Stowed Travel Height (1)

Upper Boom Articulation (3)

Lower Boom Articulation

UJI/UJN3014

25 ft 6 in (7.77m)

30 ft 6 in (9.3m)

15 ft 4 in (4.67m)

1500lbs (682kg)

10 ft 4 in (3.15m)

1600

-50 to 950

UJI/UJN3416

29 ft 6 in (8.99m)

34 ft 6 in (10.58m)

17 ft 6 in (5.33m)

1600 lbs (727kg)

10ft 4 in (3.15m)

1600

-50 to 950

UJI/UJN3818

33 ft 5 in(2) (10.19m)

38ft 5 in(2) (11.71m)

19 ft 8 in (5.99m)

1700 lbs (773kg)

10ft 4 in (3.15m)

1600

-50 to 950

UJI/UJN4321

38 ft 4 in (10.19m)

43ft 5 in (13.211m)

22ft 5 in (6.83m)

1825lbs (830kg)

10ft 4 in (3.15m)

1600

-50 to 950

1 Based on 36 in (.91m) chassis frame height

2 Add 7 in (.18m) with chassis isolation

3 Relative the the lower boom

4 Based on "HE" hydraulic power packages and pedestal main frame

( Add 300 lbs (159 kg) for units with optional "DP" or "EH" hydraulic power package)

(Add 100 lbs (46kg) for units with optional bridge main frame)

5 Estimated weight for stability Actual weight for stability must be determined by testing in accordance with ANSI A92.2 A92.2-1900 standard.

Chassis Requirements:

-

Minimum GVWR

Front Axel GAWR

Rear Axel GAWR

Minimum Curb Weight (5)

UJI/UJN3014

10100 lbs (459kg)

4000 lbs (1818kg)

7500 lbs (3409kg)

7100 lbs 3227kg)

UJI/UJN3416

29 ft 6 in (8.99m)

34 ft 6 in (10.58m)

17 ft 6 in (5.33m)

8800 lbs (4000kg)

UJI/UJN3818

33 ft 5 in (10.19m)

38ft 5 in (11.71m)

19 ft 8 in (5.99m)

10000 lbs (4545kg)

UJI/UJN4321

38 ft 4 in (10.19m)

43ft 5 in (13.211m)

22ft 5 in (6.83m)

11000lbs(5000kg)

5 Estimated weight for stability Actual weight for stability must be determined by testing in accordance with ANSI A92.2 A92.2-1900 standard.

General Specifications:

Electrical System

Desigen Voltage

Standard Insulation Gap for UJI modles

Standard Basket Capacity

Rotation

Operating Pressure - UJI/UJN 3414

Operating Pressure - UJI/UJN 3416

Operating Pressure - UJI/UJN 3818 and 4321

12 Volts DC

Category C, 46kV and below on UJI Models

42 in

350 lbs (159kg)

5400 non-continuos with mechanical stop

2000 PSI (141kg/cm2)

2200 PSI (155kg/cm2)

2500 PSI (176kg/cm2)

UTEM SkyJacker Features and Benefits

The non-overcenter articulated SkyJacker aerial lift provides a safe, versatile means of access with horizontal reach from 15 feet up to 21 feet and working heights from 30 feet to 43 feet at full elevation.

Feature: Articulated Boom Assembly

Benefit: Up and over capability permits safe access across obstacles such as parked cars, sidewalks, landscaping, etc.

Feature: Zinc Plated Pivot Pins

Benefit: Prevents corrosion, reduces maintenance and costly down time.

Feature: Non-Lube Bearings Used at all Pivot Points

Benefit: Reduced down time for maintenance.

Feature: “Feathering” Full Pressure Hydraulic Controls

Benefit: Smooth operation provides comfort and exceptional control for the operator.

Feature: Both Upper and Lower Boom Use Identical Cylinders

Benefit: Commonality of components means lower cost, less confusion and fewer parts to stock.

Feature: 540˚ Non-Continuous Rotation with Mechanical Stop

Benefit: Provides a work envelope all the way around unit with no annoying “dead spots.” It is much less complicated and requires less maintenance than continuous rotation or other non-continuous rotation systems with electrical limit switches.

Feature: Shear-Ball Rotation Bearing

Benefit: Smoother rotation and long life resulting in lower maintenance and operating costs.

Feature: Hour-Glass Shaped Worm Engages Rotation Bearing

Benefit: Prevents free wheeling in the event of hydraulic failure. Distributes load over multiple teeth plus fewer moving parts providing long life and requiring less maintenance.

Feature: Exposed End of Worm Shaft is Hexagonal

Benefit: Allows for manual rotation in an emergency or for maintenance.

Feature: Pedestal Houses Hydraulic Oil Reservoir with Sight Gauge, Oil Filter and Electrical Components

Benefit: Protected from damage yet easy to access for maintenance and service reducing end user cost.

Feature: Upper Controls with Enabling Device and Emergency Stop Located between Boom and Platform

Benefit: Provides efficient, comfortable and safe location for controls.

Feature: Boom is Fabricated of High Strength Steel Tubing with 70,000 PSI Yield Strength

Benefit: Provides maximum rigidity and comfort for operator and a safety factor exceeding ANSI/SIA A92.2-2001.

Feature: Parallelogram Chain and Sprocket Platform Leveling Housed Inside Booms

Benefit: Smooth motion for operator support and comfort, simple to maintain and protected from damage with no cylinders to bleed or repair resulting in lower maintenance costs.

Feature: Filament Wound, Oven Cured, Epoxy Resin Fiberglass Boom

Benefit: Safety and security of operator resulting from consistent structural and dielectric properties.

Feature: Gravity Actuated, Hydraulic Boom Articulation Limit Valve

Benefit: Reduced maintenance cost compared to solenoid valves or electrical limit switches.

Feature: 350 lb. Basket Capacity

Benefit: Capacity for operator, tools and necessary components to do the job.

Feature: Integral Holding Valves on Boom Cylinders

Benefit: Lock boom cylinders in position in the unlikely event of a hydraulic hose or fitting failure. Integral holding valves eliminate manifold leakage and are less susceptible to damage.

Feature: Internal Routing of Hydraulic Hoses

Benefit: Reduces damage to hoses from external sources resulting in reduced maintenance and less down time.

Feature: Cordura Sleeves Over Hoses

Benefit: Protect hoses where they are subject to abrasion reducing wear and maintenance cost.

Feature: Automatic Return to Neutral Controls

Benefit: For safety and more productivity, platform and base controls are spring loaded to return to the neutral position.

Feature: Fiber Optic System On Units with DPM and EHM Hydraulics

Benefit: Energizes the 12VDC motor/pump only when the upper controls are actuated, conserving battery life. The full pressure upper control valve is mounted at the platform eliminating the need for any mechanical linkages like fiberglass rods to operate the valve or to actuate the 12VDC motor/pump. Fiber Optics are easy to trouble shoot. A durable sheathed cable transmits the visible light signal. The fiber optic system is fail-safe. If a switch or cable becomes broken the power unit will automatically come on allowing the operator to get down.

Feature: Numerous Options are Available

Benefit: Permits customization of an aerial lift to fit each specific customer’s needs. The most popular options are listed below:

- Bridge Mount Pedestal—Maintains the center of the body floor unobstructed and available for storage

- Emergency Lowering—Allows operator to stow the aerial lift if the primary power source is disabled for any reason.

- EHM Hydraulics—Conserves fuel, reduces engine wear, reduces pollution and allows prolonged operation inside buildings without the engine running. Batteries are charged by the vehicle engine.

- DPM Hydraulics—Provides the benefits of both HM hydraulics and EHM hydraulics.

- Single Stick Control—Provides safe, convenient control of all boom functions with a single handle.

- Hydraulic Tool Circuit—Allows use of powered tools while maintaining the dielectric integrity of the insulating booms.

- Two-Speed Engine Throttle Control—Provides for additional hydraulic flow if required.

- Continuous Rotation

- Tool Tray

- Numerous Basket Configurations

- Non-Insulated Steel Booms

- 30 Feet, 34 Feet, 38 Feet and 43 Feet Working Height

- 108 Inch Long Fiber Glass Boom (78 Inch Insulation Gap) (UJI3416, UJI3818 and UJI4321 Only)

- Category B, 46kV and Below or 69kV Rating for Upper Boom (UJI3416, UJI3818 and UJI4321 Only)

- Chassis Insulating System (8 Inch Insulation Gap) (UJI3818 and UJI4321 Only)

- Thinline Outriggers

- Poly Platform Liner

- Torsion Bar

- Hydraulic Tool Circuit Relief Valve

- Manual Platform Tilt

T:\1 UTEM\UTEM Sales Manual\2008 UTEM Sales Manual\Sec2—SkyJacker\SkyJacker Features and Benefits.doc